Advertisers Printing Installs 10-Color RMGT 9 Series Perfecting Press with LED-UV Curing – Part 2

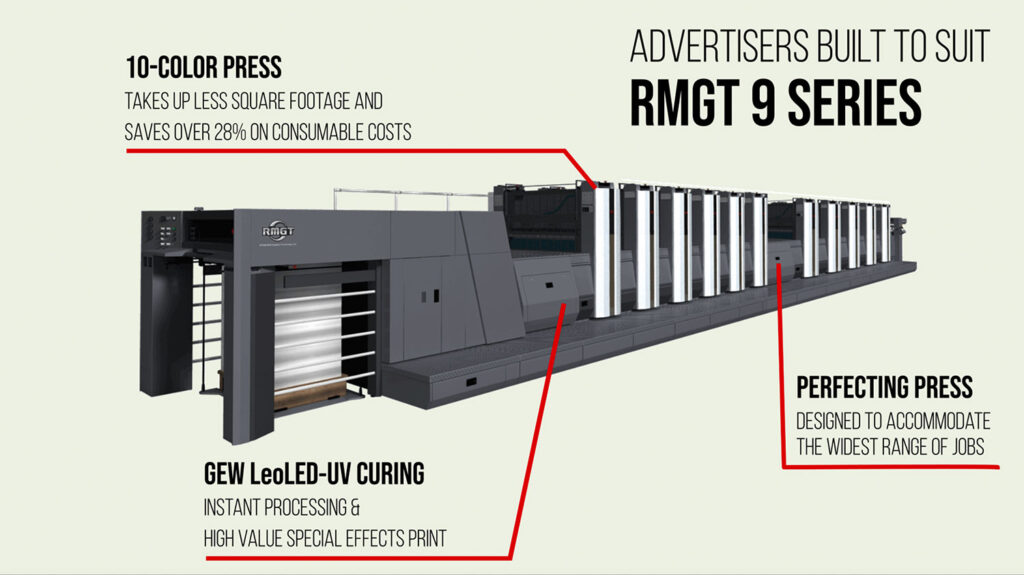

ST. LOUIS, MO – SEPTEMBER 10, 2020 — For over 97 years, Advertisers Printing has evolved as a leading commercial printer in the Midwest. Founded by Claude Fechner, the current fourth-generation Fechner management team continues a tradition of innovation by announcing the installation of a fully automated 10-color RMGT 9 Series perfecting press with LED-UV curing technology. The investment in this offset press is in line with their company philosophy of “Conscious Capitalism” and whose on-going sustainability practices are certified by SGP.

“Conscious Capitalism shapes the way we treat each and every customer,” states William Fechner, President, Advertisers Printing. “As part of our core philosophy, our ultimate goal is to enrich the lives of everyone connected with us, clients, employees, suppliers, shareholders and the community. It may not be conventional capitalism, or even business as usual, but we strongly feel it should be.” The economic impact of events such as the COVID-19 pandemic can challenge core principles as they relate to investment.

“A lot of customers have asked us why we’re investing in this new press now,” states Alex Fechner, Business Development, and fourth-generation member at Advertisers Printing. “True to our core, Advertisers has always been passionate about going above and beyond for our customers. Second, we don’t have a company without our team members. We want to do everything we can to make sure that we have a future for all our team members and their families. A third reason is the environmental angle. Investing in the 10-color RMGT 9 Series perfecting press improves our print quality and speed to market with products that offer the lowest carbon footprint.”

The acquisition of the 10-color RMGT 9 Series perfecting press allows Advertisers to eliminate three offset presses while increasing capacity at the same time. “Our equipment mix in the past has not been one-size-fits-all,” continues William Fechner, “It’s been smaller projects go on the smaller press, medium sized projects on the medium sized press, full size projects on the full size press. The RMGT allows us to cover all of that with one super automated, quick machine. We’ve been able to eliminate quarter-sized machine

Advertisers Printing follows a national trend in using a hybrid mix of offset and digital print production, with approximately 65% of their revenue still generated by offset print and 35% by digital print. Advertisers recently invested in their digital pressroom by adding a larger format HP 10000 digital press. “What the RMGT does is help to fill the capacity throughout our shop, including our digital area,” observes Alex Fechner. “This has been a really good synergistic situation. Because the 10-color RMGT 9 Series press is equipped with LED-UV curing technology, we have more flexibility to print shells LED offset and then run those shells on our HP 10000 to handle large variable data runs.”

Offset vs. Digital

Advertisers Printing follows a national trend in using a hybrid mix of offset and digital print production, with approximately 65% of their revenue still generated by offset print and 35% by digital print. Advertisers recently invested in their digital pressroom by adding a larger format HP 10000 digital press. “What the RMGT does is help to fill the capacity throughout our shop, including our digital area,” observes Alex Fechner. “This has been a really good synergistic situation. Because the 10-color RMGT 9 Series press is equipped with LED-UV curing technology, we have more flexibility to print shells LED offset and then run those shells on our HP 10000 to handle large variable data runs.”

Perfecting Press

The investment in digital machines coincides with the urgency of how quickly print work needs to be turned around in today’s print market. “Everyone always wants to hear about the printing jargon,” states William Fechner. “To put this in the simplest of terms, on our older presses, we had to print one side of a smaller sheet in one pass and then flip it over and print the other side of the sheet in another pass. With our 10-color RMGT 9 Series perfecting press, we can print a larger sheet five over five colors in one pass. Then, when you add the LED-UV curing, the sheet is instantly dry, ready to finish. This translates to more than doubling our capacity on the pressroom floor.” The new 920PF-10+CC is equipped to produce 5/5 plus in line coating and features Insta.Color makeready automation and fully automated plate-changing. This automation package plus the very compact press footprint allows Advertisers to efficiently operate their new press using one pressman.

LED-UV Curing

“We are an SGP certified company,” continues William Fechner. “One of only about 50 in the world, as far as sheetfed offset and digital printers are concerned. The RMGT 9 Series is right in the wheelhouse of being environmentally friendly. Due to LED-UV curing, it has much lower energy usage. It’s really ‘green’, with no VOCs. This better supports the health of our team and, as a result, the future of this company. Additionally, LED curing is so much faster in processing the product, helping us to serve our clients better.”

Advertisers invested in the latest GEW LeoLED-UV MLA (Modular Lamp Array) curing technology so they enjoy the ultimate in curing capabilities, flexibility and gloss level. Through a process known as “dry-trapping”, high gloss coating projects will enjoy a 10-15% higher gloss level than projects using the “wet-trap” process. When processing special projects like chemical emboss finishes, static clings and plastics the abundance of LeoLED-UV curing modules means

“In recent years, Advertisers has been competing by using our variety of smaller presses,” concludes Fechner. “In a way, we’ve been showing up to a gunfight with a knife. That put us at an unfair disadvantage, but we’ve still done well. Now with the addition of the 10-color RMGT 9 Series perfecting press, we’ve got the unfair advantage. We’re feeling confident that we’re going to be very competitive in some of these larger projects and be able to deliver faster, with higher quality, and in a shorter time. We don’t have a knife anymore… Now we’ve got a cruise missile.”

“We are very proud to work with Bill, Alex and the Advertisers Printing Team on this exciting next step in their impressive 97-year history.” states Chris Manley, President, Graphco, Distributor for RMGT in the Midwest and Southeast. “It’s a true honor to partner with such a great family business and for our industry a 10-color configuration is a very special press. As our industry continues to rebound from the low point of the V we are so proud to be aligned with a rugged company like Advertisers Printing.”

“It’s been our position since 2014 that an investment in RMGT technology dramatically improves the profitability of our customer’s offset and digital revenue stream.” continues Manley, “When we impact 65-75% of a company’s turnover the whipsaw in profit is much greater than other investments. Much better profitability from offset is extremely important, and reverse cannibalizing digital to improve margins helps immensely as well. We can hardly wait to see the benefit that Advertisers Printing will enjoy through this powerful investment.”